CGMP: What It Means for Your Medications and Why It Matters

When you take a pill, injection, or inhaler, you trust it’s safe, pure, and works as it should. That trust isn’t accidental—it’s built on CGMP, Current Good Manufacturing Practices, the set of rules that control how pharmaceuticals are made. Also known as cGMP, it’s the backbone of drug quality from factory to pharmacy. Without CGMP, there’s no guarantee your medicine doesn’t have the wrong dose, contaminated ingredients, or worse—nothing at all.

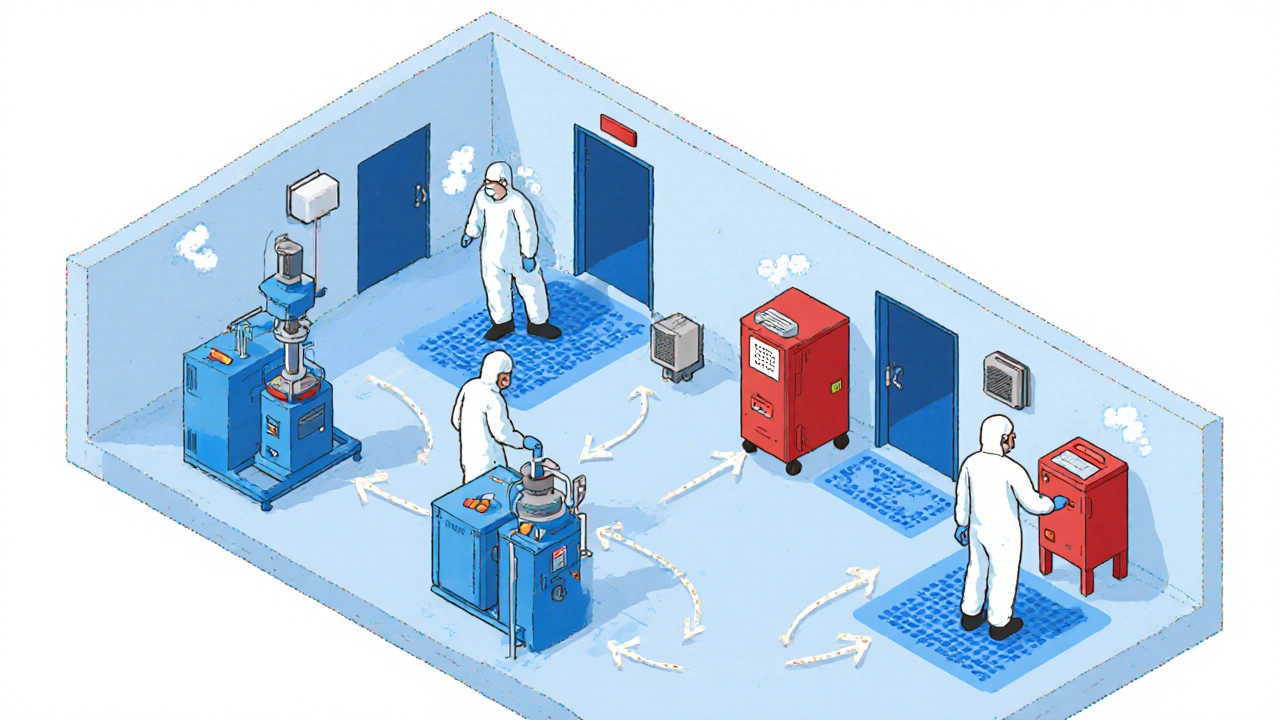

CGMP isn’t just paperwork. It’s a living system that covers everything: who handles the ingredients, how equipment is cleaned, how batches are tested, and even how workers are trained. The FDA, the U.S. agency that enforces drug safety standards checks factories worldwide—whether they’re in Canada, India, or the U.S.—to make sure they follow these rules. If a plant fails, the FDA can shut it down. That’s why you see recalls: it’s not failure, it’s the system working.

CGMP connects directly to the drugs you read about here. When we talk about injectable drug shortages, the sterile production of IV meds is one of the most tightly controlled parts of CGMP, and any tiny error can shut down a whole line. The same goes for generic drugs, which must meet the same CGMP standards as brand-name pills to get FDA approval. That’s why TE codes exist—to tell pharmacists which generics are truly interchangeable. Even sustainability efforts, like greener cetirizine production, must still follow CGMP while reducing waste. You can’t cut corners on safety, even when going green.

CGMP doesn’t just protect you from bad medicine—it protects you from the invisible risks: cross-contamination, mislabeled batches, or unstable ingredients that break down before you take them. That’s why hospital pharmacies are so strict about where they source drugs. That’s why a single batch of enoxaparin, a blood thinner, can trigger nationwide testing if one lab finds a problem. And that’s why the FDA doesn’t just inspect factories once a year—they show up unannounced.

What you’ll find below isn’t just a list of articles—it’s a look at how CGMP touches every corner of modern medicine. From the statin interactions, which depend on precise manufacturing to avoid dangerous mix-ups, to the liver transplant, where immunosuppressants must be flawless, CGMP is the invisible thread holding it all together. You won’t see it on the label. But if it’s missing, you’ll feel it.

Contamination controls in generic drug manufacturing prevent dangerous adulteration through strict cleaning protocols, cleanroom design, and real-time monitoring. Learn how facilities stay compliant and avoid costly recalls.