Contamination Control in Pharmaceuticals: Preventing Drug Safety Risks

When you take a shot, an IV, or even an inhaler, you expect it to be clean—free from bacteria, particles, or chemical mix-ups. That’s where contamination control, the system of practices that prevent harmful substances from entering medications during manufacturing or handling. Also known as sterile processing, it’s not just about cleanliness—it’s about keeping patients alive. A single contaminated vial of anesthetic or chemotherapy drug can cause sepsis, organ failure, or death. Hospitals and pharmacies don’t just store these drugs—they’re on the front line of a silent war against invisible threats.

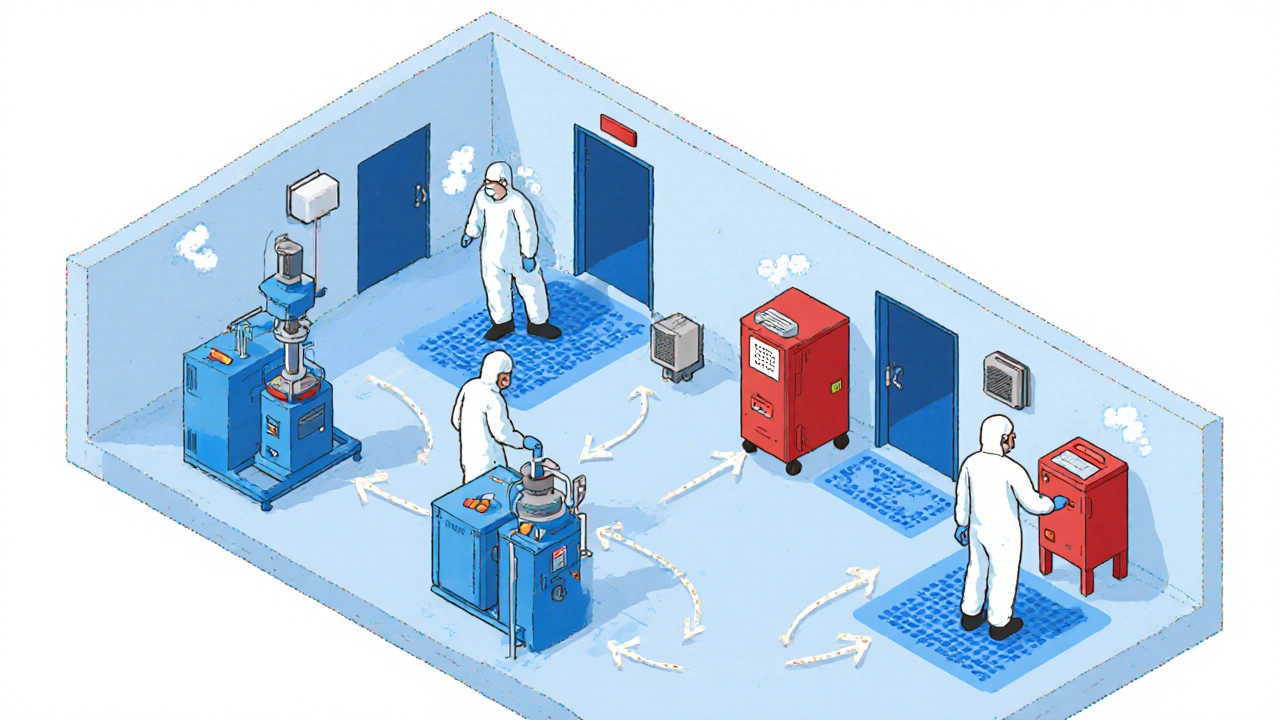

Contamination control isn’t one rule. It’s layers: clean rooms with filtered air, staff wearing gowns and masks, equipment sterilized between uses, and testing every batch for microbes. It’s why hospital pharmacies are struggling right now—when sterile injectables run short, they’re forced to stretch supplies, increasing the chance of cross-contamination. It’s why drugs like ipratropium bromide, a bronchodilator used daily by COPD patients must be made in controlled environments—because even a speck of dust in an inhaler can trigger a life-threatening reaction. And it’s why anti-Xa monitoring, a test used to track blood thinner levels sometimes becomes urgent: if a heparin batch was contaminated, it could cause unexpected bleeding or clots.

Contamination doesn’t always come from dirt. It can come from wrong ingredients, cross-mixing during packaging, or even chemical degradation. That’s why therapeutic equivalence codes, the FDA’s system for approving generic drug substitutions matter—because a generic that looks the same but isn’t made under the same clean conditions can be dangerous. Even something as simple as cetirizine, a common allergy pill, has a manufacturing footprint. If the factory doesn’t control dust or humidity, you could end up with a batch that’s less effective—or worse, unsafe.

What you’ll find below are real stories from the trenches: how drug shortages force risky shortcuts, how sterile procedures fail, how contamination shows up in unexpected places—from IV bags to herbal supplements—and what’s being done to fix it. These aren’t theory pieces. They’re case studies from hospitals, labs, and pharmacies where contamination control is the difference between healing and harm.

Contamination controls in generic drug manufacturing prevent dangerous adulteration through strict cleaning protocols, cleanroom design, and real-time monitoring. Learn how facilities stay compliant and avoid costly recalls.